Every blast chiller can be configured to adapt to the needs of restaurants, pastry shops, ice cream shops and bakeries, with dedicated configurations and programs.

Discover all features

All models come with removable tray racks, a core probe, and an electronic touch control panel.

BLAST CHILLING AND/OR FREEZING

Rapidly chill food, bringing the core of each item to 0 to 3 °C. Freeze food to temperatures of -18 °C and below.

CORE PROBE

The probe constantly measures the temperature at the core of the item and automatically manages the blast chilling and/or freezing cycles.

SOFT AND HARD BLAST CHILLING

Processing cycles with different levels of intensity, to use according to the size and type of food to freeze.

HACCP

It’s possible to verify the outcome of blast chilling and/or freezing cycles conducted overnight, with saved alerts.

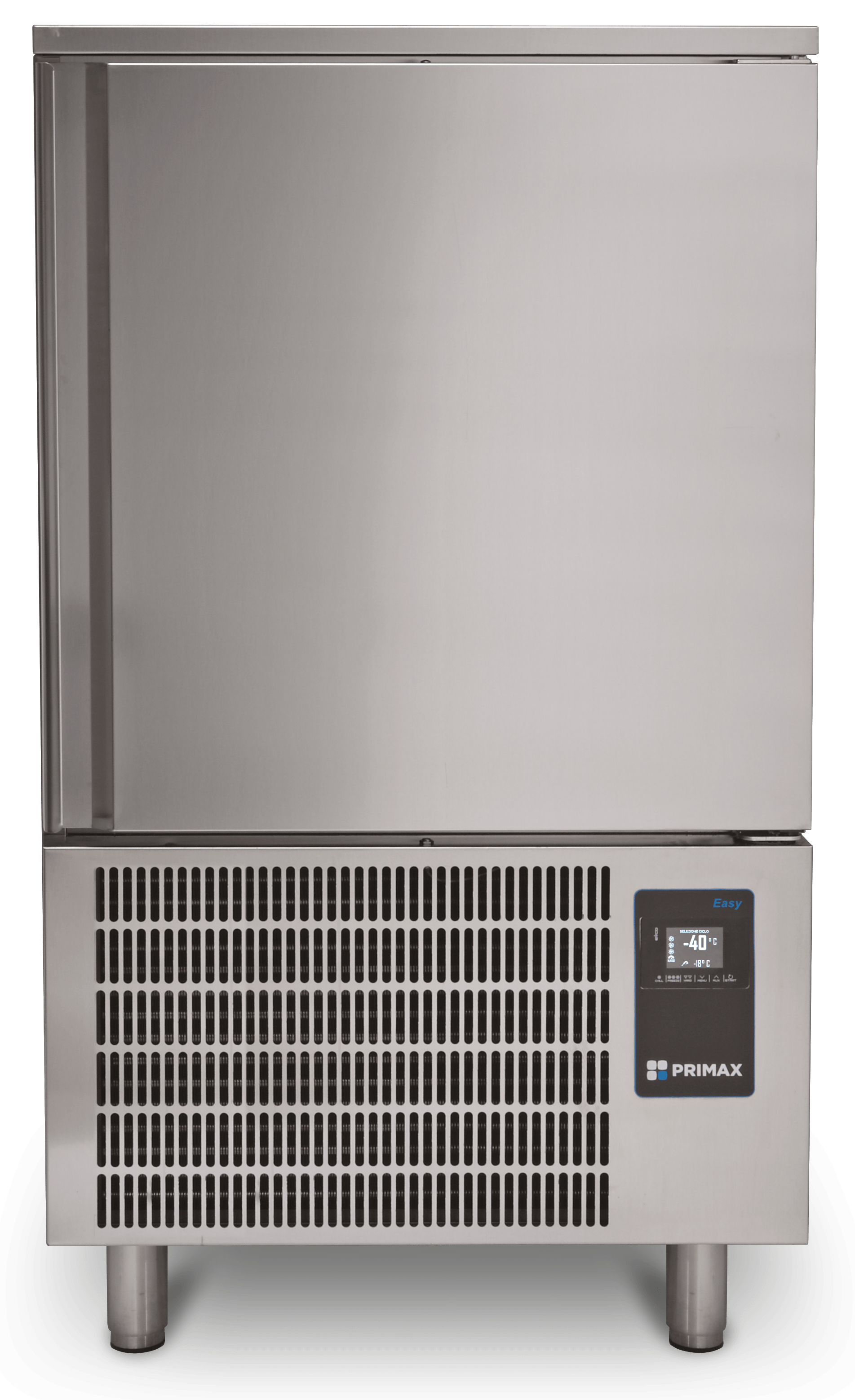

DESIGN

FUNCTIONAL DESIGN BY COLD SPECIALISTS

The design choices of our products are made to meet the needs of professional cooks and chefs, guaranteeing durability despite intense everyday use. The thick SAE/AISI 304 stainless steel structure is robust and solid. Intelligent design makes cleaning and maintenance quick and easy.

ELECTRONIC CONTROL PANEL

INTUITIVE, SECURE, OPTIMISED MANAGEMENT

Programming production cycles is even faster and more intuitive thanks to the touch panel. Specially designed features make it possible to work with delicate, easily perishable ingredients, like those often used for pastries or fine dining establishments.

FEATURES

PRE-CHILLING AND MAINTENANCE

The pre-chilling option creates the ideal conditions to start a cycle of blast chilling and/or freezing, guaranteeing high-quality results. The maintenance feature is automatically activated at the end of every cycle, ensuring the same temperature for 24 hours.

ALL-WEATHER

CLIMATE CLASS 5

Climate class 5 guarantees excellent performance even when the temperature outside is up to 40 °C with 50% humidity.

Discover the solution best suited to your needs.